Excerpts of a conversation between Akash Gupta, CEO of Clean Electric with Benedict Paramanand, Editor, SustainabilityNext

The reason I got excited about doing this interview, is a chance to demystify and break the myths about the battery industry that many of us consumers have. Before we go there, give us a sense of your company that you started in 2016, which is into manufacturing Li-ion batteries for the transport sector. What has the journey been like from 2016 to now?

Thank you. Actually, we started this venture during our BTech days at IIT BHU Varanasi. We started working full-time on Clean Electric in 2020. So, it’s been four years now, as we speak. Abhinav, Ankit and I began this full-time in 2020, leaving our jobs and starting it during the first wave of the COVID pandemic.

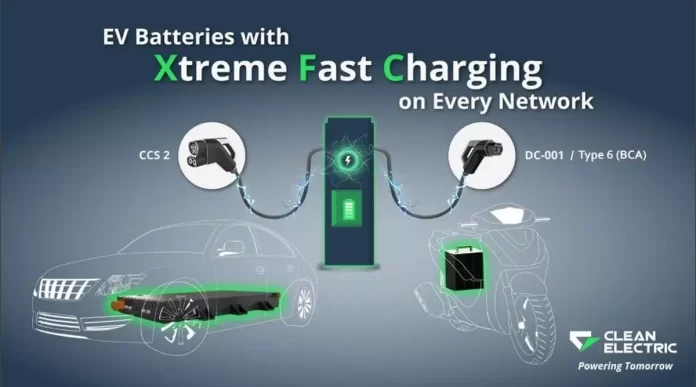

We have grown to an 80-member team. We want to solve barriers that are not allowing EVs to scale. EV penetration is still at 2–3%, because there are issues like cost and convenience. For instance, you can refuel your combustion engine car or two-wheeler in five minutes, but for an EV, it takes 60–200 minutes, to get your EV charged. This is a significant inconvenience for the average consumer when purchasing an automobile which needs to be solved. Additionally, there have been many incidents of electric vehicles catching fire.

We’ve been building EVs for 10 years now, and we have deep expertise in solving some of the key issues. We’ve built our own batteries in the past 10 years for racing events, and now they are for roadworthy legal vehicles. We have four granted patents filed in India and the US, and we are extending these patents to other geographies.

You’ve stated significant problems, and the pain points that consumer are facing, and you’ve set out to address them. So, in four years, how have you addressed that?

We have been participating in international events in Philippines and Singapore where we represented India and got top 3 ranking. We have been problem-solving. Our fleet applications and technologies are being used by companies like Blue Smart and Ola. We aim to achieve a 10–20-minute charging time. We have patents for our Li-ion batteries, and they are global patents.

It’s a very scalable technology. We are working with three-wheeler manufacturers and electric car and light commercial vehicle OEMs. This year, we have shown live demonstrations of electric two and three wheelers getting charged in 12 minutes. We have projects with reputed companies for electric cars and light commercial vehicles to achieve this as well. We have a manufacturing facility where we can assemble 100 battery packs a month, and we plan to scale up.

Manufacturing batteries in India is complex due to a lack of access to raw materials. How do you see this?

We rely on imports for cell manufacturing since there’s zero capability in India right now. However, we expect this to change in the next 2-4 years.

That’s Interesting. What’s the demand forecast for EVs in the next three years?

There have been some short-term disruptions, but over the last three to four years, EV sales have doubled every year. We expect to continue growing at a 50–70% CAGR across all categories.

And do you think battery prices will remain stable?

There might be minor fluctuations, but prices should remain in the same ballpark. The price difference between combustion engine vehicles and EVs is minimal now, especially for two-wheelers and three-wheelers.

How confident are you that India will manage the battery challenge for EV growth?

India is addressing EVs and batteries differently from the US and Europe. We have cost-efficient EVs, and our technology, which includes a 15-minute battery, is crucial. Reducing charging times can solve range anxiety, and consumers can charge their vehicles in 15 minutes, even if they don’t need a 600-kilometer range.

So, the global trend is towards a hybrid model, combining electric with either diesel or petrol. Is that the future, not EVs alone?

Hybrid vehicles are complex and expensive. Luckily, our government is futuristic and visionary, and we are making a leapfrog directly to electric vehicles. Indian OEMs are producing 100,000 cars a year and will double next year, avoiding the complexity of hybrid vehicles.

The electric powertrain and the transmission of combustion engines become more complicated, yet businesses like General Motors and others must accept this because of their heritage. Fortunately, however, Indian OEMs are either operating on CNG or electric power. Borden electric architecture, for instance, is the foundation for all of Mahindra’s electric car models and will be developed by the end of this year. Thus, unless people like Maruti influence the government in their favour, I believe India will forge ahead and immediately switch to battery electric vehicles rather than strong hybrids, as is the trend in other nations. However, I think that changing to EVs right away will be the best course of action.

So, the obvious question anyone would ask is, China has leapfrogged in EV’s, so what can India learn from them?

If you look at the Chinese car market, and they sold eight million electric vehicles. The number of cars per thousand is still very low compared in India compared to China, but it has significantly improved since pre-COVID.

We were doing 3 million EVs now. So, it’s a 50% jump in the sector, but we have to be very frugal. We have to develop our own supply chain. The Chinese government has supported a lot of OEMs. They have bailed out a lot of electric car companies, like Nio, etc, when they faced problems.

We need to start setting up our competencies, not only in manufacturing but also in all the design capabilities, whether it is about cells, batteries, or controllers. We need to be self-sufficient in terms of technology and production, and the rest will follow. The government has been proactive, but not as proactive as China in promoting their industry.

How long can we be in a protectionist economy where we open up to Chinese companies?

According to the policy, a multinational OEM is eligible for import subsidies and other benefits if they are ready to invest $500 million. If they intend to manufacture locally, they simply have to pay 15% duty rather than 100%. India has thus already adopted a globalization strategy, and the Ministry of Heavy Industries’ current regulations encourage businesses like Tesla and others to establish their production bases in India. It is therefore a smart idea to start with, as it will force current OEMs to make technical investments in order to stay ahead of the curve and prevent them from becoming complacent.

Since Indian OEMs lack resources, the government may enact new laws to level the playing field for a year or two, or until Indian OEMs reach the same level of scale and supply chain efficiency as multinational OEMs. That was the case with the steel sector. Anti-dumping duties and other measures were implemented by the government when China began to dump steel into the nation. In this way, the Indian government is very aggressive and nimble, and I believe that going forward, there will be level playing fields. Since Indian OEMs won’t get complacent at this point, it is acceptable to open up the sector. If not, they’ll assume there is nothing to worry about.

What’s your Vision for the next 3 years?

Currently, we have started the production of electric two-wheeler battery packs. We are already supplying to Bounce Infinity and other customers. The idea is to start supplying electric three-wheeler OEMs in this financial year and, going forward, to start supplying high-performance battery packs to enable Indian OEMs to compete with global players like Tesla and others because they already have a 30-minute charging capability, while Indian OEMs have a 60-minute charging capability.

So we need to support Indian OEMs with the latest global technology so that they can compete with Tesla, Kia, and other global players in their technology from the US and Europe. The idea is to penetrate across two-wheelers, three-wheelers, electric cars, electric buses, and grid storage markets.

We will focus on energy storage for the time being because the renewable energy transition also needs a lot of batteries since wind and solar are intermittent in nature. So, you need batteries to supply firm power to the grid, which is required.

For complete video – https://youtu.be/EbeimefSWmI