The building and construction industry is one of the highest emitters of greenhouse gases accounting for a staggering 37% of global emissions through the production and processing of materials like cement, steel, aluminum, and others. It is not just solid materials but excessive amounts of water are also used in construction.

In ESG parlance, embodied carbon refers to the carbon footprint of a building before construction even begins, presenting a challenge due to the lifecycle of building materials. Commonly used materials like asbestos and thermocol are derived from non-renewable sources. Continuing to build the traditional way would spell disaster, given the rising demand for housing spaces and fast-depleting natural resources.

Unified Intelligence took the problem to the drawing board. What could be used to substitute natural materials in construction? The answer was plain to see because it was everywhere – plastic.

Praveen Crasta and his team got down to business and experimented with the insulation potential of single-use plastic (SUP), multi-layered plastic (MLP) and tetra packs. Developing a prototype and rigorously testing these discarded materials under extreme weather conditions built the team’s conviction in the product. A few rounds of iteration and there it was – circular building materials that could be used to erect structures built for longevity, provide insulation and structural integrity – all while reducing the carbon footprint that comes with building a house.

Waste Plastic to High-Performance Building Material

| Details | Comparison | Terrace Living | 1 BHK Home | 2 BHK Home |

|---|---|---|---|---|

| Sq. Ft. | 170 | 340 | 550 | |

| Time Taken to Build | Thermal Panel | 4 days | 7 days | 10 days |

| Cost Range | Ready for Finishing, tiling and painting | Rs 3.5 – 4Lac | Rs 4.5 – 5.5Lac | Rs 6.5 – 7.5Lac |

Lakshmi Ravinder Nair reached out to Praveen Crasta, Founder of Unified Intelligence, to learn more about this revolutionary solution.

How did you develop an interest in innovating for the construction industry?

It started off with a college project. We had created a structure called the paper honeycomb that we could shape in a way so that it could take vertical loads. After a few trials and errors, we figured that this could be used in packaging products like ACs and refrigerators and also be made into panels to be used inside building walls. Much to our surprise, it is fire-resistant, shock-proof, and provides many other advantages.

The material also replaces thermocol and has a good recyclable value. This idea slowly blossomed into a business, and we now help package products for the white goods industry. Parallelly, we also started looking at other recyclable materials and their applications in the construction industry. That’s when we stumbled upon plastic.

Unified Intelligence uses single-use plastic and multi-layered plastic (MLP) to create insulation panels. Can you tell us a bit about how it is done and how do you think this will change the housing market?

Sure, the logistics look somewhat like this. Dry waste is collected by waste management companies who in turn segregate plastic and pass on the materials to recyclers who make sheets/panels from SUPs based on work orders. We prepare these panels and test them for use in construction.

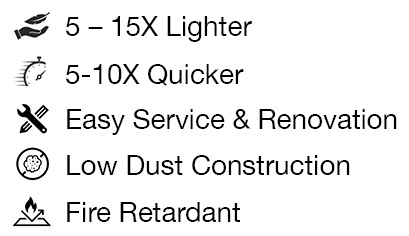

With these products, we found that we can achieve a remarkable speed of installation (it takes 7 days to build a 340 sq ft house), build in remote places where heavy equipment cannot reach and most of all provide thermal insulation where the interiors of a house remain cool despite torrid temperatures outside and vice versa.

Are these products certified?

The Indian standards for building materials are mostly created for cement, steel and brick. Currently, there is no method to qualify these products in India. However, we have approached a few academicians for their inputs and they seem quite happy with the properties of our products – more specifically, the structural integrity and thermal insulation. The other option to get these products validated for use is to go out of India and procure relevant certifications.

What is the price of these products and what is included?

Well, for a 340 sq ft house (1 BHK), we charge between INR 4.5 – 5.5 lakhs whereas for a 440 sq ft house, it can go up to 7.5 lakhs. What is included in the cost are walls, roof, a ready-to-paint surface, electrical conduits and plumbing lines. The house owner will only have to finish the house with doors, windows and other customizations.

What are the carbon emissions of these products?

To make cement, coal needs to be burnt at about 1400 degrees centigrade. Additionally, an overlooked source of emission and waste is water. A 3500 sq ft home uses an astonishing 1,30,000 litres of water in various processes. UI’s products are a dry construction. Where it gets slightly carbon-intensive is when we make the 6 mm cement boards for the sides of the panels but that is also done through thermic fluids which hold heat. You could say we probably emit 1 % or less of the usual emissions coming from the construction industry.

We also believe that homebuyers of the future will insist on procuring materials sustainably and maximising recyclability of all resources in their homes. We are focused on innovating for them and are currently researching how we can create condensation within the panels and collect water for irrigation or reuse.

That’s great. So, what is your vision for the next 5 years?

Our purpose is larger now than when we started. We hope to recycle at least 30% of India’s plastic and within the next 7 years, at least 75%. The sad part is that the six metro cities are the ones generating the huge volumes of plastic. We want to establish watertight processes, erect facilities and democratize the technological know-how to architects, contractors and system integrators who can manufacture these products in multiple locations. Also, at some point along the way, if we can educate the consumer to treat waste as wealth and find an alternative use to it, that is also going to be a success metric for us.

According to the UNEP report ‘Building Materials And The Climate: Constructing A New Future’, three overarching strategies need to be implemented together to decarbonize building materials:

- Avoid unnecessary extraction and production.

- Shift to regenerative materials.

- Improve decarbonization of conventional materials.

Self-sustaining homes powered by products like UI’s should mark the future of the industry. However, these are mostly driven by demand which is currently lacking. Unified Intelligence’s innovative approach not only addresses the growing issue of plastic waste but also offers eco-friendly alternatives for construction projects.

Realistically, given the dynamics of the construction industry, it might take a few years for circular products to become mainstream and until then, we have something to look forward to. Praveen and his team are on a trailblazing path to set a new standard in sustainable construction and resolve the plastic problem.

For more details – https://youtube.com/@vasparfoundation?si=fkhypboCLqL8S7u9

Lakshmi Ravinder Nair, Marketing Expert, BBLF & GLF