Agriculture sector in India consumes approximately 19% of India’s electricity supply. With a total of 18 million electric pump-sets receiving free or cheap electricity, the net result has not only been a subsidy outfl ow of over INR 20,000 crore for electric pumping, but also inefficiency in energy and water-use.

With the need to signifi cantly expand area under irrigation – only 45% of India’s agricultural land is irrigated – energy and water demand from pumping is only going to increase. This state of affairs is clearly not sustainable and greater efficiency and lesser wastage in resource-use is the order of the day.

Bureau of Energy Effi ciency (BEE) has estimated a saving potential of 25%, or 33 TWh annually, through effi cient pumping. Since nearly a quarter of our electricity is lost during transmission and distribution, this translates to 44 TWh of power purchase avoided by DISCOMs, reducing their costs by more than INR 15,000 crore, and reducing state subsidies by over INR 5, 000 crore annually. This requires an additional INR 54,000 crore of investment in efficient pumps

Farmers have found themselves devoid of financial capacity and/or incentives to migrate to efficient pumps. In most instances, rich farmers benefit from poor targeting or implementation of state subsidy policies. Even the supply to agriculture is not metered as diligently as for other sectors, since state governments subsidise it for end-users.

Therefore, even though a clear business case exists for energy effi ciency (EE) in pumping, skewed incentives ensure that these low hanging fruits remain unexploited.

Agricultural Demand Side Management

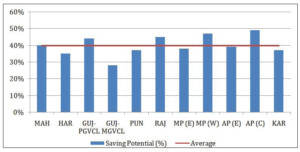

In order to tap these savings, BEE launched the AgDSM scheme, whereby it would undertake replacement of inefficient pumps by effi cient ones through an Energy Service Company (ESCO), at no additional cost to the farmer. For the 20,750 pumps audited by BEE on 87 feeder lines across eight states, an average annual savings potential of 40% (96 GWh) was assessed, yielding a payback period of 3-4 years).

BEE engages the services of Energy Efficiency Services Limited (EESL) to implement AgDSM schemes using innovative business models. It provides an overview of a standard model, where EESL enters into a MoU with DISCOM and conducts energy audits, pump replacements and M&V based on its own resources, and shares the energy savings obtained from efficient pumps with the DISCOM.

The first phase of Hubli Ag DSM project in Karnataka covered 600 pumps and provided 37% energy savings. The second phase will cover 10, 000 pumps. Detailed Project Report for first the phase of BESCOM Ag DSM project covering 1 lakh pumps has been prepared, while replacement of 1,500 pumps in Mysore has been initiated. Similar proposals for Haryana and Rajasthan have been approved by respective governments. EESL estimates an investment of INR 1,000 crore for Ag DSM in the next 2-3 years.

Barriers and Recommendations

The limited experience with Ag DSM has highlighted numerous design and implementation challenges. It is questionable if the annual savings reported are sustainable, given the complex environment Ag DSM is operating in. This is indicated by the fact that the demand for AgDSM projects has not picked up commensurately with the demonstrated savings.

Some of the key issues and possible solutions are presented below:

1. Monitoring and Verification: Due to an absence of uniform M&V practices, there have been numerous instances of delays in project implementation. Proper metering of electricity supply is the first step towards baselining energy-use. It will also help utilities plan better and manage procurement more efficiently. Credible M&V reduces risks and delays, and builds positive outlook towards EE projects in the financial sector.

2. Financing: Ag DSM projects face difficulty in obtaining loans due to high risk perception, lack of exposure to DSM financing, and weak M&V protocol. While ESCO based model partially overcomes this through performance guarantees, national and state funds (PRGF and SCEFs, respectively) can help leverage private finance through financial risk-guarantees.

3. Acceptance by farmers: Farmers view the monitoring of consumption with suspicion, and are generally averse to pump replacement, since detailed site assessments show smaller optimal pump-size. Systematic awareness and publicity campaigns on the benefi ts to farmers, greater grass-root NGO involvement, and recognition through energy and water conservation awards can help overcome this scepticism.

4. Quality of Electricity Supply: Poor supply quality results in overdrawal, lower field efficiencies, and frequent pump failures. Unorganised sector pumps are designed to absorb the impact of variable voltages; this resilience comes at the cost of efficiency. Predictable and quality power supply is critical to reduce performance risk, increase farmers’ acceptance and improve bankability.

5. Institutional capacity: DISCOMs and State Designated Agencies (SDAs) are constrained due to lack of skilled personnel, institutional mechanisms, and prior experience in utility-ESCO partnership based EE projects. Each SDA must have an EE cell to inform the policy-makers and set targets. DISCOMs should be able to provide assistance in AgDSM implementation by providing reliable data and infrastructure.

6. Star-rated pumps: Studies have shown that only a fraction of marketed pumpsets are from standardised ISI-marked brands. MSMEs dominate the market; and their technical capacity must be augmented to conform to minimum performance standards. Complementarily, unlabelled pumps should be gradually phased out.

7. Electricity pricing: Steady increase in agricultural tariffs provides monetary incentives for farmers to switch to effi cient pumps. This should be complemented with better supply quality and grid expansion to reduce dependence on inefficient diesel pumps.

Conclusion

Unlike other demand side management projects, AgDSM faces numerous complexities on account Mohd. Sahil Ali is a Senior Research Economist. At CSTEP, he works on energy efficiency, demand side management, and other low carbon technology and policy options. of its site-specifi c nature, interaction with a large unorganised sector with low technical and financial capacity, political factors, and adverse starting conditions in terms of baselining and measurement. This has resulted in numerous challenges, which have impeded the scaling up of Ag DSM. Irrigation pumping represents a leaky bucket whereby only a fraction of resources provided actually benefit the end-user. The underlying conditions responsible for this leakiness must be addressed in an era where energy production and consumption will continue to get more expensive.

The limited experience with Ag DSM has demonstrated the benefi ts available to be tapped. A strong political will coupled with an unwavering commitment to transparency and accountability will send a positive message to the stakeholders determined to make transformative changes in this sector.