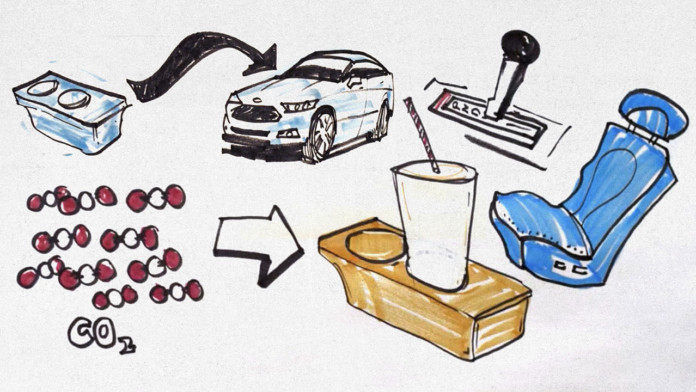

Ford Motor Company is the first automaker to formulate and test new foam and plastic components using carbon dioxide as feedstock. Researchers expect to see the new biomaterials in Ford production vehicles within five years.

Formulated with up to 50% CO2-based polyols, the foam is showing promise as it meets rigorous automotive test standards. It could be employed in seating and underhood applications, potentially reducing petroleum use by more than 600 million pounds annually– enough to fill nearly 35,000 American homes. CO2-derived foam will further reduce the use of fossil fuels in Ford vehicles and increase the presence of sustainable foam in the automaker’s global lineup.

For nearly two decades, researchers have worked successfully to develop sustainable materials for Ford products. Soybeans are turned into seat foam; kenaf is used in door bolsters; recycled T-shirts and denim go into carpeting; and recycled plastic bottles become seat fabric.

Ford began working with several companies, suppliers and universities in 2013 to find applications for captured CO2. Among them is Novomer – a New York-based company that utilizes carbon dioxide captured from manufacturing plants to produce innovative materials. Through a system of conversions, Novomer produces a polymer than can be formulated into a variety of materials including foam and plastic that are easily recyclable.