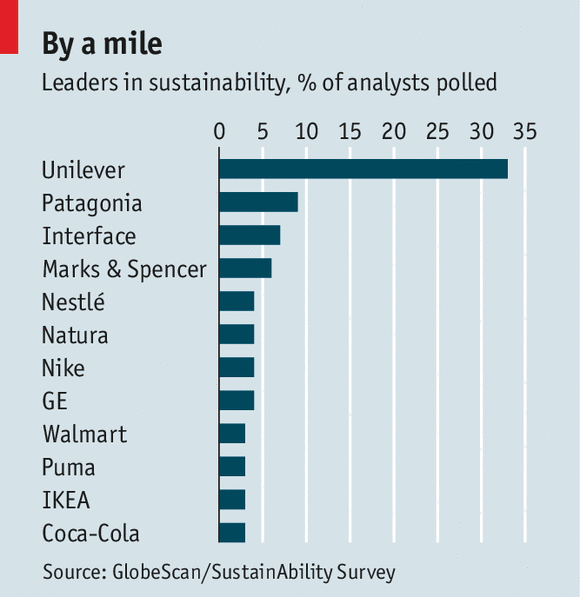

Unilever again showed it is the world’s leader in practicing sustainability when it announced recently that it has saved 1 million tons of CO2 throughout its manufacturing network since 2008. Just three months ago Unilever announced its success with zero waste to landfill across its global factory network.

The company also said its energy consumption has decreased by 20 percent — the same energy used to run 40 factories or the equivalent in carbon absorbed by over 800,000 acres of forest in one year — which has resulted in significant cost savings of 244m.

“We’re delighted to have hit this milestone in our CO2 reduction,” Unilever Chief Supply Chain Officer, Pier Luigi Sigismondi said. “Reducing our energy consumption not only cuts our greenhouse gas emissions — the equivalent in carbon of 800,000 acres of forest each year — but also cuts our costs. Since 2008, we’ve saved over 244m by reducing our CO2 emissions.

“Climate change is having a huge impact on the environment and on business. Ahead of Climate Week in Paris, we are continuing to show that sustainability is a driver for growth, and the only long-term option for business in a volatile world.”

Unilever said how it was able to achieve CO2 savings:

• In South Africa, a bi-product of the seed oil from Flora, Stork, Rama and Rondo brand oils is used to fuel factory boilers.

• In the UK Marmite factory, 18,000 tons of solid Marmite waste is converted via an anaerobic digester into methane, which is used to provide 30 percent of the factory’s thermal energy.

Helping Others

Unilever is also helping other industries to reduce their carbon emissions. In Indonesia, waste from Unilever’s operations goes into another company’s cement as a material, helping to reduce the carbon impacts of the cement industry — the sixth-largest contributor to greenhouse gas emissions in the world.

Unilever, which has been assessing its greenhouse gas emissions since 1995, has proven that reducing energy use not only benefits the environment, but has a clear business purpose as it helps to drive down costs and leaves the company less exposed to changes in the energy price market, improving business resilience.

The company has a clear strategy to switch to renewable energy. Currently, 28 percent of the energy used by Unilever factories comes from renewable sources, with 39 percent of electrical energy produced from this source.

Unilever has a target to reach 40 percent renewable energy by 2020 and plans to work towards 100 percent. It joined the RE100 campaign to accelerate the scale-up of renewable power. The goal of RE100 is – at least 100 of the world’s most influential businesses to commit to switching to 100 percent renewable sources of electricity in the near future.

Related Reading http://www.economist.com/news/ business/21611103-second-time-its-120-year-historyunilever- trying-redefine-what-it-means-be