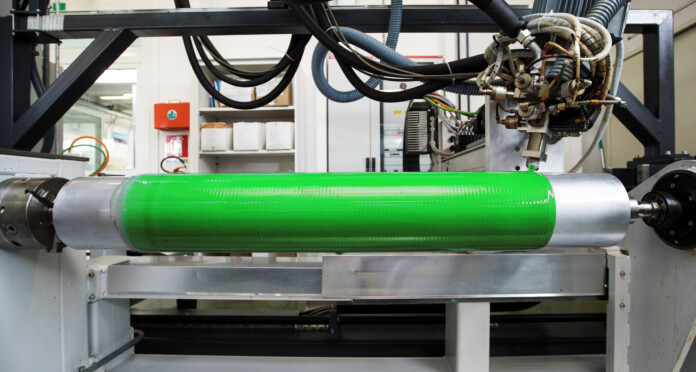

LANXESS is a specialty chemicals company. It is increasingly using bio-based or recycled raw materials in its plastics production. A new variant of the composite Tepex is 100% based on the biological raw materials flax and polylactic acid. “We have combined fabrics made from the natural flax fibers with bio-based polylactic acid as a matrix material and thereby developed a composite manufactured entirely from natural resources. We are now able to produce it to a level of quality suitable for large-scale production,” Stefan Seidel, head of Tepex Research and Development at LANXESS said recently.

The material is suitable for use in sports articles, in the production of automotive interior parts and in electronics for case components. LANXESS produces the composite at its site in Brilon, Germany.

Tepex can be recycled completely. After its use, the product can be shredded and easily processed into new plastic.

LANXESS also relies on sustainable raw materials for its Durethan brand polyamide-6 plastics. In the latest product, 92% of the raw materials have been replaced by sustainable alternatives; the long-term plan is to increase the proportion to 100 percent.

The sustainable origin of the raw materials is certified according to the rules of ISCC Plus (“International Sustainability and Carbon Certification”) using the mass balance approach. This method compares the quantities of raw materials used with the quantities of products produced and creates an accounting link between input and output, similar to the purchase of green power.

In the production of the high-performance plastic, LANXESS uses “green” cyclohexane from sustainable sources such as rapeseed oil or other biomass as raw material. For the supply of “green” cyclohexane LANXESS has entered into a strategic cooperation with energy company bp. The high-performance plastic is also reinforced with 60 percent by weight of glass fibers recycled from industrial glass waste.

The alternative raw materials are chemically identical to their equivalents of fossil origin. Therefore, the plastic has the same properties as its fossil-based counterpart. It was developed at the LANXESS site in Dormagen, Germany, and is manufactured at the site in Krefeld, Germany.

“A climate-neutral future can only become a reality if we increasingly use sustainable products,” says Frederique van Baarle, Head of the High Performance Materials business unit at LANXESS.

New “Scopeblue” brand label

In the future, LANXESS will add “Scopeblue” to its most sustainable products. The brand label marks products that either consist of at least 50 percent circular (recycled or biobased) raw materials or whose carbon footprint is at least 50 percent lower than the one of conventional products. LANXESS is a leading specialty chemicals company with sales of EUR 6.1 billion in 2020. The company currently has about 14,800 employees in 33 countries. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.