The high demand for sand has led to environmental concerns because of the dependency on riverbed sand. Alternate materials such as sand made by crushing sedimentary rocks can be considered as a viable alternative to riverbed sand in order to meet the demand. This sand has higher efficiency rate too, says Shyam Sunder P of CSTEP

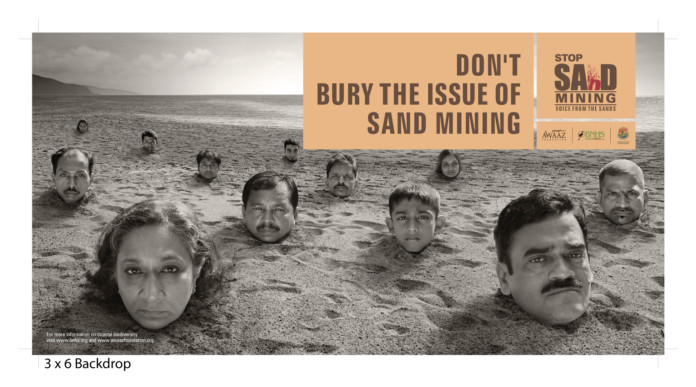

Sand is an essential element in concrete and hence plays an important part in the construction and infrastructure industry of a modern economy. It is the primary raw material in concrete and is typically sourced from riverbeds, which are usually ecologically sensitive areas. Excessive mining leads to the degradation of riverbeds, which affects the local groundwater system, biodiversity and the recreational potential of these places.

Karnataka officially produces 9 Million tonnes (Mt) of sand per year, and a large part of this quantity is currently sourced from riverbed mining. Some sand is also imported from neighbouring states. The Center for Study of Science, Technology and Policy (CSTEP) recently conducted a study which estimated the current demand for sand in Karnataka as 26 Mt (in 2014) with an expectation to grow to 56-81 Mt per year (by 2030). Due to the high demand for sand (as compared to supply), the state has observed high sand prices leading to an increase in construction costs. The high demand for sand has also led to environmental concerns given the dependency on riverbed sand. Alternate materials such as sand made by crushing sedimentary rocks can be considered as a viable alternative to riverbed sand in order to meet the demand.

Manufactured Sand

Crushed-stone sand or ‘manufactured sand’ is produced by crushing rocks to a grade comparable to that of natural sand. A study was conducted by the Department of Civil Engineering, Indian Institute of Science (IISc) for the Department of Mines and Geology, Government of Karnataka (GoK) on the suitability of manufactured sand as fine aggregates in mortars and concrete. The study reported that while the physical characteristics of manufactured sand are similar to riverbed sand, the concrete made has higher compressive (6-9%) and flexure (12-15%) strength. The technical analysis showed that manufactured sand is suitable for applications in mixtures such as mortar and concrete.

Popularity of Manufactured Sand in Karnataka

The current production and use of manufactured sand is estimated to be 3Mt per year in Karnataka. Mining rules set by the state have been drafted to encourage sand manufacture from allotted quarries. Several independent manufacturers and popular cement manufacturers can benefit from these rules. Recently, the State Cabinet decided to provide 5% subsidy on interest for loans taken to set up manufactured sand units in districts which lack natural sand resources (as reported in The Hindu). In order to create demand, the State Government has also encouraged the use of manufactured sand in all government contracts. Today, the Bangalore Airport and the Bangalore Metro are some of the major projects that have utilised manufactured sand.

Availability of Resources

CSTEP’s study shows that Karnataka has adequate resource to meet the demand for sand for several decades. The study examined the potential for manufacturing sand from existing mines with expired leases, existing mines given area extensions as well as unexploited open rock formations (using satellite maps and GIS – Geographic Information System). After excluding ecologically sensitive areas and areas close to human built environments, the study estimates that there are adequate rock resources available to meet the growing demand for sand in the state.

According to the study, the state has a manufacturing sand capacity of about 40 Mt from inactive mines, about 70 Mt by expanding quarry areas and about 3075 Mt from un-exploited resources. While these numbers have been calculated using desk-based geo-spatial tools, verifying the same based on ground surveys will be necessary.

Beyond Manufactured Sand

With increasing urbanization and Government push for ‘Housing for all’ the demand for building materials will continue to increase. The identification of alternate building materials will play an important role in meeting some of the demand. With ageing infrastructure, the disposal of debris will become an important issue. Relying on fresh raw materials including manufactured sand may not be sustainable. It will become necessary to examine the potential of converting debris to sand. Recycling demolition waste is an exercise worthy of examination.

Policy Recommendations

Based on superior technical performance and the availability of manufactured sand resource, and the need to develop manufactured sand capacity in Karnataka, the following recommendations have been proposed:

i.Publicise and promote manufactured sand by highlighting the results of the IISc study on the superior properties of manufactured sand

ii.Mandate the use of manufactured sand by the Public Works Department (PWD), Irrigation Department, and Urban and Rural Development Departments

iii.Revisit the existing tendered quarries to encourage the production of manufactured sand

iv.Identify and demarcate zones for new stone quarries and crushing areas before auctioning and leasing parcels. Provide access and associated infrastructure such as roads, electricity, etc. to these zones

v.Provide structural and financial incentives for stone crushers to engage in the production of manufactured sand

vi.As a long-term plan, the Government should explore the potential of utilising building debris or new building materials to produce sand and adopt innovative architecture.

vii.Encourage more manufacturers in the process to build ready capacity

viii.Include mandated Occupational Health and Safety (OHS) processes to support human resource at mining and manufacturing sites

The government, through its forward- looking policies has the power to create a conscious and focused “reduce, re-use and recycle” strategy which can make a significant impact on making India an environmentally sustainable society.

Shyam Sunder P. is a senior research engineer working in the areas of energy efficiency, low carbon investigations, spreadsheet and computational models for energy, emissions and life cycle assessments at CSTEP. shyam@cstep.in

Nice..! Thanks for sharing your knowledge Tavara Mines and Minerals