Bharath Bakaraju, the Founder and CEO of Phyxx44 Labs, has ingeniously designed milk without carbon while preserving the taste, texture, and consistency. He says, “We’re creating nature-identical, cell-derived alternatives to your favourite dairy products. Same taste, Zero Carbon footprint and Happy Cows.”

Bharath is an engineer from IIT Kharagpur in Industrial Biochemistry and has an MBA from IIM Lucknow. He is passionate about curbing anthropogenic effects and promoting climate advocacy.

In a chat with Snigdha Voruganti, a guest reporter at SustainabilityNext, he outlines the new product’s immense potential globally, pricing model and launch plans. He is confident of the positive environmental influence of lab-grown dairy in reducing global carbon emissions. Edited excerpts:

Is there a product ready to be released into the market? Have you filed for a patent?

The initial release of our inaugural product, Animal-Free Whey Protein, is scheduled for the market’s introduction by late 2024 or early 2025. This product will be accessible as a key ingredient for food companies. This patent-pending product (PCT filed) promises enhanced functional and health benefits for consumers.

Please tell me a bit about your professional life.

Originally from Hyderabad, I spent the majority of my 15-year career working in consumer internet technology-driven product businesses as a Product Lead at Google, concentrating on Search Experience. Recognizing the substantial impact, I could have in the dairy sector; I made the bold decision to leave a lucrative and comfortable job.

What was your motivation to get into the milk products venture?

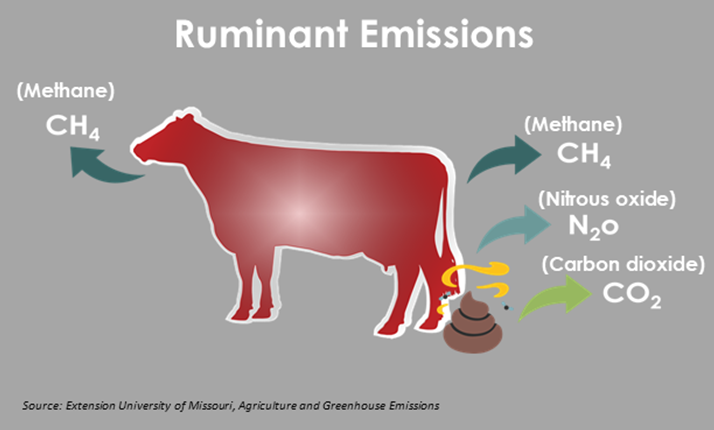

Animal-based food systems globally emit more greenhouse gases than the entire transportation sector combined. However, when it comes to funding and entrepreneurial initiatives to tackle this issue, the automotive industry garners more attention than the dairy sector. This paradox fuelled my interest in creating a carbon footprint-free dairy industry.

Our business model will initially involve serving as a B2B supplier of dairy ingredients to companies that utilise conventional dairy elements, such as whey concentrate, whey isolate, and caseinate.

What does Phyxx44 stand for and how do you envision its future?

44 is the molecular weight of CO2. So, the name means ‘fix CO2 i.e., fixing carbon’. The start-up is focused on creating nature-identical dairy without animals, using a technology called precision fermentation of microbes. To succeed, we need to outperform animals in milk production in terms of speed and cost-efficiency. By 2035, we anticipate that one-third of consumption will shift to alternative proteins, making animal-based products a minority.

Why is dairy bad for the planet?

The global population, currently at 7.5 billion, is expected to reach 9-10.5 billion in 20-40 years. Beyond this growth, a significant portion of the population, due to income constraints, cannot regularly afford animal-based proteins in their diets, adding complexity to this narrative. Also, a rapid surge in demand due to a rise in income accentuates the importance of assessing the sustainability of current food production methods.

Evaluating food system sustainability involves analysing vital aspects affecting long-term climate change: land use, water consumption, and greenhouse gas emissions. For instance, beef production utilises an astonishing 15,000 litres of freshwater per pound. Substituting beef with plant-based options can significantly reduce land and water use and cut carbon emissions by 90%, a trend mirrored in dairy alternatives.

To produce one litre of cow’s milk, we consume 650 litres of fresh water, release more than 3.2 kilograms of carbon dioxide, and use up approximately 9-10 square metres of land that becomes unusable over time. This isn’t sustainable. India, the largest global dairy consumer, annually produces and consumes around 226 million metric tonnes of milk, resulting in significant CO2 emissions.

How important is taste a factor in transition?

Switching to soy milk alone reduces land use, water use, and greenhouse gas emissions by approximately 90%, offering a more sustainable alternative. But the taste of soy milk is a big issue. If you can’t address the taste factor, you can’t resolve the dairy-carbon gas issue. This is why we’ve embraced technology that preserves taste by replicating the same molecular structure– Recombinant Protein Production.

Could you explain the process of recombinant protein production and its use as an alternative to milk proteins?

Consider yourself a chef who faithfully follows a recipe book. Now, imagine if I inserted extra instructions that seamlessly blend in with your book, the result would be a dish infused with those added elements. This is akin to what we do with microbial cells. The recipe book, in this case, is the genome, the extra instructions are the recombinant gene, and the protein is the organism’s output. When you scrutinise a cow’s genome, you pinpoint details that guide milk fat production. This genomic data is then translated into a language understood by a simpler organism, like yeast. Through genetic engineering, you incorporate this information into yeast, effectively transforming small yeast cells into micro-cows.

It facilitates the creation of milk that replicates the cow’s molecular structure. It has the same taste, texture, and metabolic properties as traditional milk. Precision fermentation alternatives allow for similar products with environmental benefits.

Could you highlight successful instances of recombinant protein production for human consumption?

For almost three decades, this technology has been transformative. Cheese production, for instance, depends on the enzyme chymosin, typically found in animals. Yet, due to its scarcity worldwide, most cheesemakers utilise recombinant techniques. Insulin, coronavirus vaccines, and even detergents are made using this approach. Recently, we’ve realised that this technology extends to creating directly consumable food products as well.

What are your plans for production?

We aim to utilise India’s high-quality, cost-effective research and manufacturing capabilities for producing the product locally. Manufacturing will occur across both our proprietary facilities and contracted manufacturing units within India.

What challenges do you foresee in developing a carbon-free dairy?

I’d categorise this into three stages: the early phase, the current status, and the future perspective. Initially, building a like-minded team and securing funding posed challenges, especially in India where sustainable start-ups often face longer revenue-generation timelines.

At present obtaining fermenters is a major obstacle as larger companies dominate the supply. Looking ahead, ‘Made in India’ doesn’t hold the same value as ‘Made in the USA.’ Phyxx44 could become a “Designed in India but Made in the USA” brand, necessitating a focus on international markets for the prosperity of Indian sustainable start-ups.

Is there any estimation of the pricing for your milk?

As we are not directly involved in formulating and retailing liquid milk to consumers, we currently lack an estimated cost for this. Nevertheless, if we were to speculate on the potential cost, it might hover around INR 200 per litre for end consumers. Presently, dairy alternatives mostly fall within the range of INR 120 to INR 300 per litre. However, the higher price is rationale because of higher initial manufacturing costs. These costs are expected to gradually decrease and align with standard product pricing (around INR 60-65 per litre) by 2027 because of operational efficiency and manufacturing scale.